Processpumpar

Model EV-S Dry Vacuum Pumps

Efficient and energy saving

The need to reduce energy is a major subject for sustainability. Manufacturers employ large numbers of aging dry vacuum pumps. Depending on the process, the vacuum system alone can contribute up to 60% of the total electricity demand for a process tool. Upgrading the vacuum pumps can reduce the fab’s energy consumption and save your money.

EBARA has developed a new and more efficient vacuum pump designed by improving motor efficiencies, optimized number of compression stages, enhancing motor control and adding intelligent communications, the energy consumption of the dry pump will be significantly reduced. This results in lower operation costs and improved profitability for our customer.

Key features

- Lowest power consumption: Decreased user’s Cost of Ownership and reduced company’s carbon emissions

- Smaller weight and dimensions compared to earlier models: User friendly

- No N2 purge in clean applications: No nitrogen required

- Flexible rotation speed and idle mode as standard: Further power saving

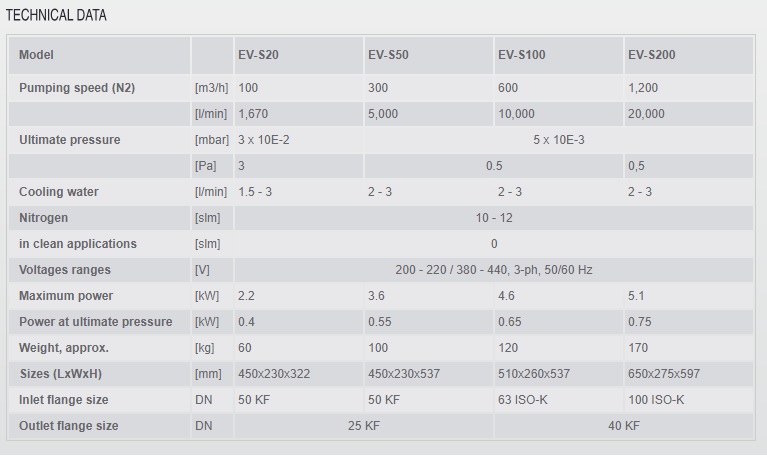

Technical Characteristics

- Multi-stage lobe design engineered for application in clean and medium harsh processes as Load Lock, SEM, PVD, Ashing, Ion Implantation and Etch

- Main pump and booster pump with energy saving DC motors

- Intelligent control system

- Low noise and low vibration

- Adjustable pumping speed by RPM variation

- Very small footprint

- Low consumption of electrical power, cooling water and nitrogen

- Idle mode for additional energy savings