Natur- och biogasanalys

Precisive® 5-242B natural gas pipeline analyser

Real-time analysis of natural gas composition

Precisive® 5-242 is a real-time hydrocarbon gas analyzer calibrated for natural gas composition monitoring and heating value analysis. This package is optimized for gas-phase product analysis containing C1-C6 alkane gases typically found in natural gas pipeline and LNG.

Precisive® 5 Application-specific Analyzers are focused on the oil & gas markets for a variety of natural gas and hydrocarbon processing applications. From upstream gas processing, to midstream distribution and downstream refining and power generation. The unique Precisive® TFS™ platform further lends itself to a diverse set of monitoring points from bulk high percentage level compositions, fast response bulk BTU and Wobbe Index monitoring, through to trace ppm (part per million) trace impurity in natural gas, refinery gas and ambient air conditions.

Key features

- Natural gas composition monitoring (distribution, storage, metering, blending, processing)

- Natural gas compression stations

- Check metering, blend monitoring, fast-response BTU monitoring

- Natural gas based power generation (turbine, combustion engine, fuel cell)

- Fast-response alternative to traditional gas chromatograph type instruments

- Detect pipeline product change – over as much as 60x faster

Precisive TFS™ Light Absorption Spectroscopy

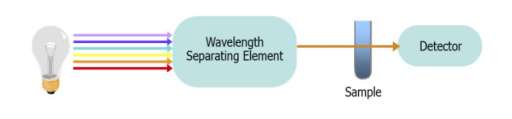

The Precisive TFS™ (Tunable Filter Spectrometer) sensor platform consists of a light source, a sample cell (for gases, liquids or solids), a wavelength separating element (spectrometer) and a photo-detector. The wavelength separating element “slices” the wavelength components of the broadband light source which then interacts with the sample molecules. Some of the wavelength components are absorbed and some are transmitted through without any absorption.

Advanced Spectral Decomposition Algorithm

Precisive TFS™ Tunable Filter Spectrometers use an advanced spectral decomposition algorithm. The resulting spectrum is called absorption spectrum, which acts as “fingerprints” which are used to identify the sample components and/or quantify the composition of the sample.

Precisive® 5-242B Natural Gas Pipeline Analyzer Benefits

- Analysis in seconds: Real-time, continuous measurement suitable for process control applications with robust feedback control eliminating the need for complex feed-forward modeling.

- No carrier gas or fuel gas requirements: Low operational costs for remote and unattended use with minimal infrastructure requirements making it suitable for small scale plants.

- Robust calibration: Full hydrocarbon speciation without columns with less than 0.2% zero-drift per month.

- Flow-through sensor design: No sensitivity to pressure and flow variations minimizes potential sampling and phase change issues.

- Compact, outdoor-rated, low-power: Well suited for transportable spot check applications with a NEMA4X / IP66 enclosure that can be engine or manifold mounted.