Tillbehör

Pincetter

Micto to Nano™ Tweezers

Micro to Nano offers a wide selection of tweezers to cover virtually all applications areas.

The choice of tweezers includes both general tweezers and highly specialised tweezers. The tweezers are divided in five distinct groups:

- EM-Tec high quality tweezers, high precision tweezers for EM, sample prep and special applications in microscoscopy. Made from anti-magnetic stainless steel, titanium or carbon fiber filled plastics

- EM-Tec SEM stub gripper tweezers are special tweezers to handle the grooved pin stubs and the cylinder stubs varying in size form 10-32mm diameter.

- EM-Tec special tweezers for Gatan 3View pins and Cryo grid boxes

- Micro-Tec tweezers for AFM application to handle AFM/SPM cantilevers and AFM discs, made from anti magnetic stainless steel

- Value-Tec general purpose and industrial tweezers are fine, medium and strong tweezers with an excellent price point.

The comprehensive selection:

The EM-Tec high precision anti-magnetic tweezers are Swiss made high quality tweezers with smooth edges and a matte finish to reduce glare. They are made from a special, low carbon, high strength stainless steel. This tough material exhibits good corrosion resistance to salts, low concentrate acids, solvents, oils and greases. Good wear resistance against most materials. Although an anti-magnetic alloy is used for these high precision tweezers, it is not recommend to use them in strong magnetic fields or for handling magnets. Use Titanium or plastic tweezers for strong magnetic fields. Application fields for the EM-Tec high precision tweezers are wide ranging and include: sample handling, microscopy preparation, sorting, precision manufacturing, electronic assembly, watch making, general laboratory, biological and medical applications. Offered are 13 different styles of tweezers and a set of 5 in a protective foam lined plastic wallet.

Material for EM-Tec high precision anti-magnetic tweezers

Specifications of the EM-Tec hig precision anti-magnetic tweezers:

These superior biology tweezers are made from the C-Star Ni-Cr-Mo super alloy. The profile and shape of the EM-Tec high biology tweezers has been optimised for delicate and ultra-high precision tasks in biology, microscopy, medical and micro-engineering fields. These biology tweezers can be continuously used at 600°C and exhibit excellent shape retention, fatigue resistance and extraordinary wear resistance.

TSB 50-003030 Material for EM-Tec biology C-Star super alloy tweezers

Specifications of the EM-Tec ultra-precision biology tweezers:

The EM-Tec high precision anti-magnetic reverse action tweezers are Swiss made precision engineered high quality tweezers. They are also called self-closing, crossover or X-type tweezers. These excellent self-closing tweezers exhibit smooth edges and a superior matte finish to reduce glare. They are made from a special, low carbon, high strength stainless steel to provide:

- The right tension for the self-closing tweezers

- Excellent mechanical strength

- Good corrosion resistance to salts, low concentrate acids, solvents, oils and greases

- Good wear resistance against most materials.

Material for EM-Tec high precision anti-magnetic tweezers

Specifications of the Value-TecEM-Tec high precision reverse action tweezers:

The tweezers and the locking mechanism are made from a special, low carbon, high strength stainless steel. This tough material exhibits good corrosion resistance to salts, low concentrate acids, solvents, oils and greases. Good wear resistance against most materials. Although the alloy used is an anti-magnetic, it is not recommend to use these tweezers in strong magnetic fields or for handling magnets. The application fields for the EM-Tec high precision tweezers are wide ranging and include: sample handling, microscopy preparation, sorting, precision manufacturing, electronic assembly, watch making, general laboratory, biological and medical applications. Offered are 6 different styles of locking tweezers.

Material for EM-Tec hig precision anti-magnetic locking tweezers

Specifications of the EM-Tec hig precision anti-magnetic locking tweezers:

The application fields for the EM-Tec high precision mini tweezers are wide ranging and include: sample handling, microscopy preparation, sorting, precision manufacturing, electronic assembly, watch making, general laboratory, biological and medical applications. Offered are 4 different styles of tweezers.

Material for EM-Tec high precision anti-magnetic tweezers

Specifications of the EM-Tec hig precision anti-magnetic mini tweezers:

Ideal for reaching into tight places and when working with chemicals or heat sources; they are longer than the standard high precision tweezers. They are made from a special, low carbon, high strength anti-magnetic stainless steel.

Material for EM-Tec high precision anti-magnetic tweezers

Specifications of the the EM-Tec hig precision anti-magnetic tweezers:

The EM-Tec high precision titanium tweezers are made from tough, strong and lightweight titanium Grade 1. Titanium exhibits good corrosion resistance to salts, low concentrate acids, solvents, oils and greases. Titanium has a combination of unique properties:

- fully non-magnetic – ideal for handling magnets or when a strong magnetic field is present

- high strength to weight ratio – excellent choice for precision repetitive tasks

- high melting point and can be used up to 870°C – high temperature use

- bio-compatible – maintain cell integrity in biology, medical and histology

- good wear resistance – clean room compatible material

- cold formable and high ductility – ideal for handling brittle materials like silicon or glass.

The application fields for the EM-Tec high precision titanium tweezers are wide ranging and include: sample handling, microscopy preparation, biological, medical, histology, precision manufacturing, magnetic, cleaning and high temperature applications. Offered are 7 popular styles of tweezers and a set of 5 in foam lined plastic wallet.

Material for EM-Tec high precision titanium tweezers.

Specifications of the EM-Tec high precision titanium tweezers:

The EM-Tec high precision super alloy tweezers are made from a special Ni-Cr-Mo super alloy. This super alloy is about six times harder than anti-magnetic stainless steel with the highest hardness at the tips. These super alloy tweezers can be continuously used at 600°C and exhibit excellent shape retention, fatigue resistance and extraordinary wear resistance.

Material for EM-Tec high precision super alloy tweezers.

Specifications of EM-Tec high precision super alloy tweezers:

The EM-Tec high precision cutting tweezers feature precision ground edges for precise cutting of fine wires. Made form hardened tool steel to ensure durability. Intended for cutting soft copper, gold, silver, aluminium and magnetic wires. Ideal for cutting tabs from tabbed TEM grid and cutting TEM grids to make custom FIB grids. It is advisable to keep these cutting tweezers clean and use oil to protect against corrosion. Choice of 4 popular styles, including the EM-Tec 152.S mini-cutting tweezers. The high quality, Swiss made EM-Tec high precision cutting tweezers feature:

- hardened steel cutting blades with precision ground edges

- smooth wide handles for asserting pressure

- matte anti-glare finish

- choice of angled or parallel blades for smooth cutting action

- cutting of soft copper, gold, silver, aluminium and magnetic wires

TSB 50-005152 Material for EM-Tec hardened stainless steel tweezers

TSB 50-005015 Material for EM-Tec high precision cutting tweezers

Specifications of the EM-Tec high precision cutting tweezers:

The application fields for the EM-Tec ESD safe epoxy coated anti-magnetic precision electronic tweezers are wide ranging and include: sample handling, microscopy preparation, sorting, precision manufacturing, electronic assembly, watch making, general laboratory, biological and medical applications. Can be continuously used at up to 120°C. Offered are 9 different styles of the ESD epoxy coated tweezers.

TSB 50-001905 Material for EM-Tec ESD safe epoxy coated precision electronic tweezers

Specifications of of the EM-Tec ESD safe epoxy coated anti-magnetic precision electronic tweezers:

The SEM stub gripper tweezers are all made from anti-magnetic stainless steel and are clean room compatible. The selection of the EM-Tec SEM stub gripper tweezers comprises gripper tweezers for:

- grooved pin stubs with 12.7mm, 25.4, 19 and 32mm head diameter

- JEOL cylinder stubs with 9.5, 12.2, 25 and 32mm diameter

- Hitachi cylinder stubs with 15, 25 and 32mm diameter.

TSB 50-050012 Material for EM-Tec SEM stub gripper tweezers

Specifications of the EM-Tec SEM stub gripper tweezers:

The EM-Tec 553.AM precision cryo grid box handling tweezers are especially designed for handling the small cryo grid boxes used for storing TEM grid under liquid nitrogen. They can be used with the EM-Tec GB4 cryo grid box and other cryo grid boxes of similar design with a rotating lid and a central screw to hold the lid. With these tweezers you can pick up de cryo grid box by holding the head of the screw on the top. Designed for Ø5mm screw heads, but can be used for screw head sizes Ø3mm to Ø6mm. Length of these tweezers is 145mm.

The high quality, Swiss made EM-Tec 553.AM precision cryo grid box handling tweezers feature:

- polished edges for good contact,

- added length for safe handling in LN2

- matte anti-glare finish

- serrated handles for extra grip

- Cryo compatible, low carbon austenitic stainless steel

- optimized for Ø5mm screw heads (can be used from Ø3-6mm)

Material for EM-Tec 3View stub and cryo grid box tweezers

The EM-Tec CGT1 gripper tool design includes spring-loaded vice grips to keep a secure hold on the pin type lid. The hexagonal shape of the barrel provides a firm grip for unscrewing the lid of the cryo grid box. A useful and practical tool for handling the cryo grid boxes under LN2. Made from cryo compatible aluminium.

- Spring-loaded vice grips

- Use with EM-Tec CGB-7 pin type cryo grid box

- Hexagonal barrel for firm grip

- Cryo compatible aluminium construction

The Micro-Tec AFM / SPM cantilever tweezers are useful tools for securely and easily picking up AFM / SPM cantilevers. The AFM / SPM tips are mostly supplied in Gel-Pak boxes and need to be gently lifted of the adhesive layer. The specially formed tip enables gripping at the side of the cantilever and pulling the silicon cantilever from its packaging. They are available in anti-magnetic stainless steel and titanium in the same design with a length of 118mm. Both materials are clean-room compatible.

- Anti-magnetic stainless steel AFM/SPM tweezers are intended for standard AFM / SPM cantilevers/tips and standard applications. Satin polished surface. Not recommend for use in or near magnetic fields.

- Premium titanium light-weight, fully non-magnetic AFM / SPM tweezers especially made for magnetic tips and for those users who prefer lighter cantilever tweezers. Matte blue anodized surface.

TSB 50-040001 Material for Micro-Tec AFM-SPM cantilever tweezers

TSB 50-040004 Material for Micro-Tec titanium AFM-SPM cantilever tweezers

The Micro-Tec AFM / SPM disc gripper tweezers are designed to pick up stainless steel AFM / SPM discs. The shape of the tips fits around the edge of the discs. Ideal when picking up the AFM / SPM discs from a flat surface after mounting a sample.

The tips are not coated and have straight, fine edges for better grip. Available for the popular Ø12mm and Ø15mm AFM / SPM discs. Made from anti-magnetic stainless steel with a satin surface; 115mm long.

TSB 50-040012 Material for Micro-Tec AFM-SPM disc gripper tweezers

The EM-Tec 521.AM Gatan 3View stub handling tweezer are especially designed for handling the Ø2mm thin pin of the 3View system stubs used in the Gatan 3View system. They are designed as side grippers for easy gripping and holding the Ø2mm pin to facilitate handling and storing the 3View stubs. Length of these precision tweezers is 118mm.

Features of the high quality, Swiss made EM-Tec 521.AM Gatan 3View stub handling tweezers are:

- polished edges for good contact

- matte anti-glare finish

- side grippers

- serrated handles for extra grip

- low carbon anti-magnetic stainless steel

- optimized for Ø2mm pin of the Gatan 3View sample stubs

TSB 50-001521 Material for EM-Tec 3View stub and cryo grid box tweezers

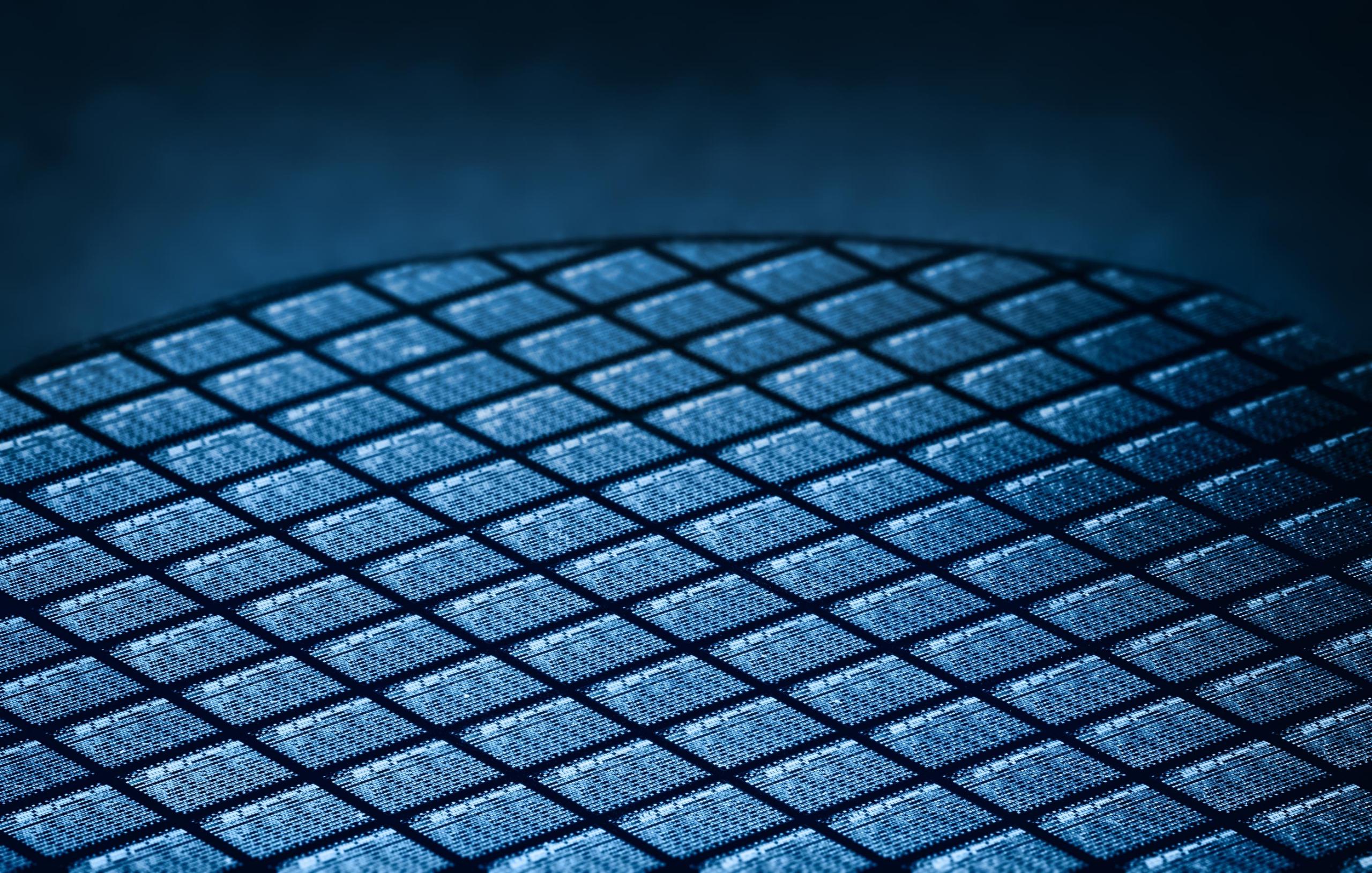

The EM-Tec precision wafer handling tweezers are made from conductive anti-magnetic stainless steel. They exhibit a larger stepped bottom paddle to support the wafer and a clamping top with posts. They are available in sizes for 2”, 4”, 6” and 8” wafers to cover the full range from 1” to 8” wafers. The 2” wafer tweezers can be used for both 1” and 2” wafers. The 4” wafer tweezers are equally useful for 3” and 3.5” wafers. The high quality, Swiss made EM-Tec precision wafer handling tweezers feature:

- smooth polished edges for good contact

- top parallel with base to reduce stress

- serrated handles for improved grip

- matte anti-glare finish.

- low carbon anti-magnetic stainless steel

- good chemical resistance to harsh solvents

- moderate corrosion resistance to acids.

Material for EM-Tec high precision anti-magnetic tweezers

Specifications of the EM-Tec precision wafer handling tweezers:

The EM-Tec ESD safe carbon fibre reinforced plastic tweezers intended for handling of scratch sensitive or brittle materials, magnetic materials and for harsh chemical applications. These high quality Swiss made tweezers are available in two materials:

- EM-Tec CT tweezers are made from poly vinylidene fluoride (PVDF) reinforced with 30% carbon fibre. ESD safe, tough material with excellent chemical resistance.

- EM-Tec CN tweezers are made from the engineering plastic polyamide66 reinforced with 30% carbon fibre. ESD safe, strong material with excellent wear and abrasion resistance. It has a lower cost compared to the CT material.

Chemical compatibility plastic material chart

Material for EM-Tec CN carbon fibre reinforced polyamide ESD safe plastic tweezers

Specifications of the EM-Tec CN polyamide carbon fibre reinforced ESD safe plastic tweezers:

Specifications of the EM-Tec CT PVDF carbon fibre reinforced ESD safe plastic tweezers:

Plastic Replacable Tip Tweezers

ESD safe soft plastic tipped tweezers are ideal for handling scratch sensitive materials such as aluminium, brass, copper and plastics. The softer plastic tips are also better for handling silicon chips or glass to avoid damage and debris. When the tips are worn out or damaged they can be easily replaced with another pair of precision tips, which are separately available.

Chemical compatibility plastic material chart

Specifications of the the EM-Tec CT ESD safe replaceable plastic tip tweezers:

ESD Ceramic Replacable Tip Tw.

The ESD safe ZE tips exhibit both high strength and high hardness with excellent chemical stability and high temperature stability (1400°C). The hard surface makes the tips extreme wear resistant. Other advantages of the ESD safe ZE ceramic tips are no open porosity and a relative low density (light). Applications for the EM-Tec ZE ESD safe replaceable ceramic tips tweezers include handling of ESD sensitive components, hard materials, handling of samples or components during thermal, chemical and soldering processes. Generally used where very rigid tips are required.

Material for the EM-Tec ZE ESD safe replaceable ceramic tips

Specifications of the EM-Tec ZE ESD safe replaceable ceramic tips tweezers:

The ceramic ZC tips exhibit both high strength and high hardness with excellent chemical stability and high temperature stability (1400°C). The hard surface makes the tips extreme wear resistant. Other advantages of the ZC ceramic tips are no open porosity and a relative low density (light).

Material for the EM-Tec ZC replaceable ceramic tips

Specifications of the EM-Tec ZC replaceable ceramic tips tweezers:

The Value-Tec general purpose tweezers are made from solid stainless steel and intended for general purpose applications. Solid stainless steel provides good corrosion resistance against weak acids, salts, oils, and solvents. Superior corrosion resistance compared to nickel plated carbon steel tweezers.

- Fine tip tweezers in 15 different styles and a set of five in a plastic pouch. Made from non-magnetic stainless steel. Smooth grips, non-serrated tips. For magnetic fields and magnets use fiber reinforced plastic or Titanium tweezers.

- Fine tip reverse action tweezers with self-closing tips to hold samples without pressing the handles. Available in 4 popular styles.

- Flat tip tweezers offered in two styles. For handling delicate parts such as cover glass, small wafers, quarts substrates, stamps, foils etc. Made from non-magnetic stainless steel with smooth tips with serrated grips.

- Sorting tweezers (also known as diamond or jewelry tweezers) are ergonomic, long slim tweezers which rest against the hand and are ideal for sorting and handling small parts, seeds, gem stones, grains and samples. Choice of 6 different models. Available with fine tips, lightweight titanium, black epoxy coated, strong tips and locking tweezers.

- Soft tip tweezers with glass fiber reinforced polyamide tips and magnetic stainless steel grips. Offered with pointed and blunt tip. Ideal for scratch sensitive and softer materials.

Material for Value-Tec fine, industrial and fibre grip tweezers

These tweezers are made with stainless steel handles to which the ceramic tips are attached. The material used for the ZTA ceramic tips is a zirconia toughened alumina (ZTA). This is the material of choice for high temperature applications. The ceramic ZTA tips combine high wear resistance, high hardness and high temperature stability (1400°C) with good chemical stability. The hard surface makes the tips highly wear resistant.

Specifications of the Value-Tec ZTA ceramic tip tweezers:

The Value-Tec fibre grip strong tweezers are made from magnetic stainless steel for greater strength. They include fibre cushioned grips for improved handling. These strong tweezers or forceps are intended for larger and heavier items. The tips are serrated for improved grip on parts or samples. Solid stainless steel provides good corrosion resistance against diluted acids, oils, fuel, solvents, salts and most chemicals. The fibre grips is more comfortable and provides thermal insulation when working at elevated temperatures such as in soldering applications. Smooth polished satin finish.

- straight, long and slim tweezers/forceps with pointed serrated tips and 165mm length

- reversed tweezers/forceps with straight blunt serrated tips and 165mm length

- reversed tweezers/forceps with angled blunt serrated tips and 165mm length

- straight, long and slim tweezers/forceps with blunt serrated tips and 200mm length

Material for Value-Tec fine, industrial and fibre grip tweezers

Specifications of the Value-Tec fibre grip strong stainless steel tweezers:

The Value-Tec strong industrial tweezers or forceps are made from solid magnetic stainless steel. Magnetic stainless steel combines strength, toughness and good corrosion resistance for these larger industrial tweezers. Designed for handling, picking, sorting, assembling and cleaning applications. Good tweezers to carry around in the field for sample preparation, repair, assembly, geological, archaeological and forensic applications.

Material for Value-Tec fine, industrial and fibre grip tweezers