Ytmodifiering

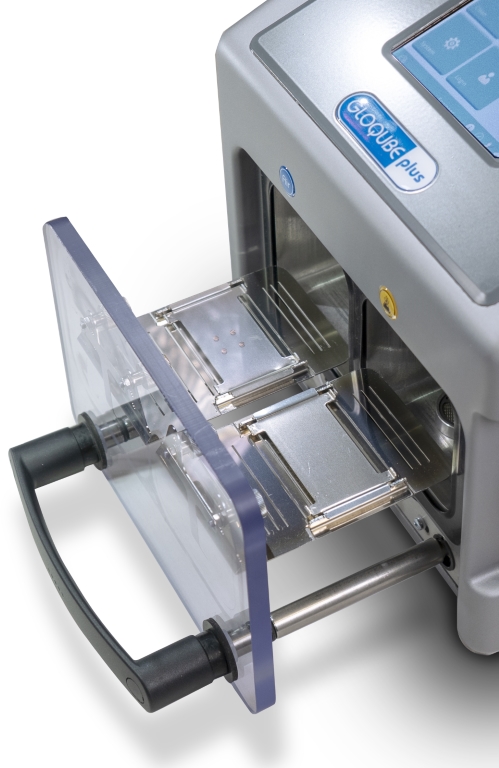

GloQube® Plus

Automated dual-chamber glow discharge system for TEM grids and surface modification

A compact, easy-to-use, fully automated glow discharge system. The two chambers enable the user maximum flexibility to choose which sample preparation technique they want to use: glow discharge in-air or in-chemical vapour, without downtime for cleaning or the risk of contamination and loss of samples.

The GloQube ® Plus has a a single door with two independent vacuum chambers and adjustable sample stages. The in-air chamber is for simple glow discharge hydrophilic applications, while the in-vapour chamber is designed for hydrophobic (negative or positive) conversions, typically using reagents such as methanol and amylamine. The automatic valve system allows greater control over the introduction of chemical vapour into the chamber.

Each of the twin chambers can accommodate two 25 x 75 mm glass microscope slides or TEM grid holders. The stages are height adjustable and fitted with removable glass slide holders. The door and stages can be completely removed for convenience and to allow easy access for chamber cleaning.

Key features

- Automatic control of vapour and air introduction

- Flush and purge cycles of vapour chamber and gas line

- Two chambers for separate in-air and in-vapour processes without contamination* * Only one chamber can be used at a time

- Fully automatic

- Loaded with typical standard recipes

- Password protected user profiles and programmable user recipes

- Negative and positive discharge modes

- Single door for easy sample loading

- Adjustable three height sample stage

- Intuitive touch screen control

- Safe vapour delivery using septum-sealed vials

- Automatic valving between chambers to prevent cross-contamination

- Fast and/or soft venting options

- Extended warranty option

Benefits

- Short in-air cycle time

- Second chamber for separating in-air and in-vapour processes

- No cross-contamination between chambers due to post-process flush cycle

- Automatic vapour delivery ensures reliable and reproducible results

- Purge cycles reduce water vapour and oxygen concentrations, ensuring excellent yield of specifically orientated macromolecules

- Adjustable slow vent time to minimise sample disturbance

- Optional fast vent for rapid process times

- Safe handling of reagent

- Three level adjustable height sample stage ensures repeatable results

Applications

- Hydrophilisation and cleaning of TEM grids carbon support films* for better sample

spreading - Improved adhesion and orientation of proteins, nucleic acids and antibodies

- TEM grid preparation for nanoparticle studies

* Typically: Formvar®, Lacey Carbon, Holey Carbon, Continuous Carbon, Quantifoil®

Surface modifications

| Surface state | Charge | Atmosphere | Typical applications |

| Hydrophilic | Negative | Air | Hydrophilisation and cleaning of carbon coated TEM grids |

| Hydrophilic | Positive | Air 1 | Nucleic acid adhesion to carbon films |

| Hydrophobic 2 | Positive | Alkylamine | Controlled orientation and improved adhesion of negatively charged proteins, antibodies and nucleic acids |

| Hydrophobic 2 | Negative | Methanol |

Controlled orientation and improved adhesion of positively charged protein molecules (e.g. ferritin, cytochrome c)

|

1) Air followed by post-treatment with magnesium acetate by the user. *

2) Hydrophobic, as noted above, may represent a less hydrophilic sample of less than 90 degrees contact angle.

Specifikationer

Leverantör

Tillbehör

TEM grids and support films

We have a large selection of high-quality grids and ready-to-use…